Examples of work

Laser Interlocks

Every laser lab is fitted with our bespoke Laser Interlock safety system. Most lasers have a connection that must be shorted in order for the laser to emit. This connection is usually a port on the rear panel of the laser driver/power supply. This port is connected by a cable to a box containing relays that will create the short. This box is in turn linked to the main control unit that monitors if the door is opened and the bypass has been activated using a code on the keypad entry box. This entry box also displays the laser status.

If the door is opened without the bypass activated, the short will be broken and the laser will cease emission.

There are some cases where interrupting the laser in such a way may be damaging, so a laser shutter, that blocks the laser beam when the interlock is tripped, can be used.

High-power, high-speed piezo driver, version 1

The images below show the development of a high-power, high-speed driver for pulsing high-power piezos.

The instrument can supply up to 220V pulses at 400KHz. Both parameters are capable of being fine-tuned to hit the narrow ‘sweet spot’ of the target system. The pulses are modulated with a low frequency pulse chain. The low frequency has fine tuning capability as well as to give added control. This instrument pulses the power piezo which in turn forces a small vacuum chamber to oscillate up and down. The particles inside the chamber then bounce up and down allowing for the particle to be optically trapped and then the physics experiments begin. At the core of this system is a high end PIC32 microcontroller..

High-power, high-speed piezo driver, version 2

The original piezo driver, although a success, was much improved upon after a second instrument was requested.

The first design was very inefficient due to the design being based around single ended switch topology. This means that massive pulse energy was wasted. The second instrument was designed around half-bridge topology thus ensuring extremely high efficiency. This allowed for more functions to be added such as pulse-width modulation (PWM) of the fast high voltage pulses, which allowed for more tuning capability.

It also allowed for the instrument to be a fraction of the size and a fraction of the weight. To give an idea of this the high voltage storage capacitors in the first one were 16000μF, whereas in the second the were 1000μF. The transformer in the former was 8Kg, in the second it was 1Kg.

High-power LED colour light driver unit

This is an 256 bit RGB light chamber. A sample would be placed into the chamber and be exposed to a various wavelengths of high powered LED light. The user interface was designed to be intuitive.

Pump valve controller unit

This control system was deigned to prolong the life of vacuum pumps. This was achieved by switching on 5 pumps and 5 valves in a programmable timing sequence as opposed to the pumps being on all of the time. At the heart of this system was a high end PIC32 microcontroller which had the desired timing capabilities to accomplish the task.

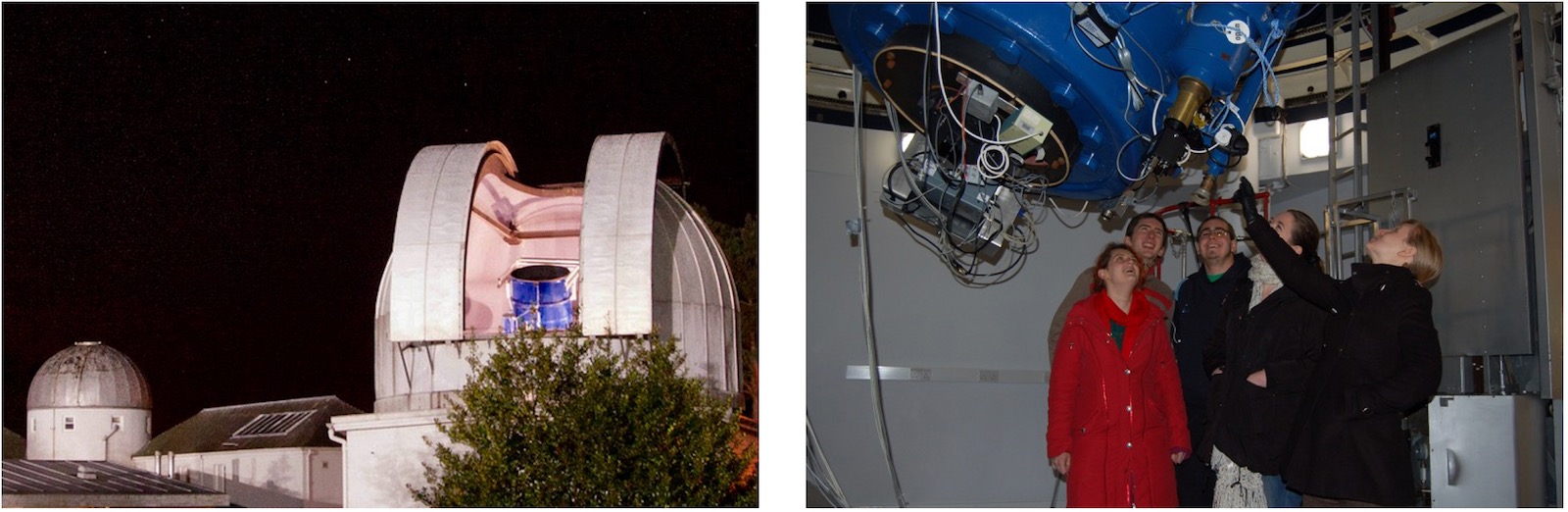

Observatory

We have carried out a vast array of work at the observatory. This has ranged from designing control and drive units for the control of the ‘legendary’ Gregory telescope to designing dome control systems for the smaller domes. A lot of this work has been interesting, for example interfacing sixty year old electronics to modern designs. We continue to support Aleks regularly with electrical and electronic work.

Gas Detection System

The above units were designed primarily for supporting a gas detection system. The electronics embedded in these units are aged as they were designed in 2006. For more information on this project please visit:

http://research-repository.st-andrews.ac.uk/handle/10023/731

Hotplate & Temperature Controller

Earth & Environmental Sciences required several hotplates that they could heat up to a maximum temperature of 180 degrees C and maintain it. 2 cartridge heaters and a thermocouple were placed in the hotplate (made by our colleagues in the Mechanical Workshop) and a controller unit was built, using a CAL PID temperature controller module. To date, 4 of these have been made.

Light Sheet Microscopy Temperature Controller

Embryos are placed on a glass slide and immersed in a water bath. The embryos degrade depending on temperature so a heating system was required to keep the water temperature at 37 degrees C. The best solution was to fit 2 cartridge heaters into the stage and build a temperature controller using an Arduino to monitor the temperature via a thermistor and control it using a PID algorithm and solid state relay.

Bat Cage Temperature Controller

A cage for bat research is controlled from 25-40 degrees celsius with a tolerance of +/- 0.2 degrees celsius. Controlling the temperature of air is difficult due to the large time constant, this was done by delicate, manual tuning of the PID algorithm. Below is a picture of the setup – bat not included.

REPAIR

A lot of instrumentation can be repaired by our technicians, often to component level without a schematic diagram.

IN DEVELOPMENT

Having designed and implemented the siderial drive on the James Gregory Telescope for quite a while now, an ambitious development is currently underway. The shutter system on the JGT is now being upgraded to a remote control system driving a high power dc motor allowing the shutter to open and close. Such a modification will implement an important safety feature meaning the user will not have to climb steps in the dark to connect the shutter cable. It is also a major step forward in the task of making the shutter computer controlled. Below is a bench prototype of the system.

With such an exponential rise in electronic technology it is very difficult to keep up to date with everything. We therefore try to learn as required when new projects arise. One such way to learn is the use of development boards as shown above. If any member of staff suggested it may be of good use to learn a particular skill we would give it consideration.

With such an exponential rise in electronic technology it is very difficult to keep up to date with everything. We therefore try to learn as required when new projects arise. One such way to learn is the use of development boards as shown above. If any member of staff suggested it may be of good use to learn a particular skill we would give it consideration.